> Research & Science

Not all zinc oxides are the same

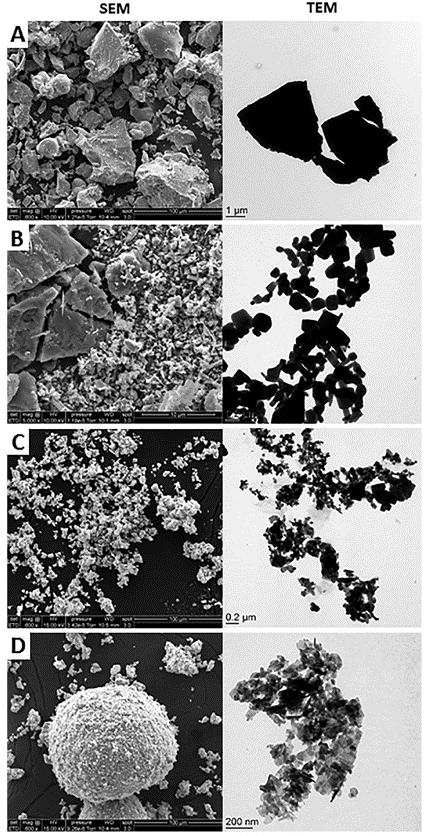

Metal oxides are a versatile group of semiconductors that are employed in a broad range of applications including micro/nano-electronics, photocatalysis and thin-film devices. As such, manufacturers of digital equipments have a wide choice of metals and oxides. Feed manufacturers also have a wide choice of feed grade zinc oxide sources, as recently shown in a scientific paper. The study collected 34 samples from the feed industry in Europe, Asia and Americas. They were analysed on 7 physicochemical parameters: Specific surface area, aggregate median diameter, agglomerate median diameter, agglomeration ratio, powder density, tapped density and Hausner ratio.

A principal component analysis allowed sorting ZnO samples in three clusters having different physicochemical properties. It confirmed that zinc oxides proposed to animal nutritionists are produced from very different manufacturing processes, thus affecting their final specifications.

Because the solubilisation of zinc compounds is a critical step in their performance, correlation analysis disclosed the most relevant physicochemical characteristics affecting dissolution of tested ZnO products: density, agglomerate size and specific surface area. Dissolution kinetics of supplemented zinc is a key parameter to assess the fate of the metal in the digestive tract. It will impact the effect on intestinal microbiota and on the bioaccessibility of the metal. Bioavailability requires the mineral source to be « biosoluble », i.e. to liberate the ionic form of the metal at absorption site. It can be concluded that differences in bioavailability from feed grade zinc oxides (see AniMag 4) can be explained by their physicochemical differences.

Source: Powder Technology 378 (2021) 746–759